OVERVIEW OF UV LIGHT TO COMBAT THE CORONAVIRUS FOR WATCHMAKING PURPOSES

There has been a lot of craze about the possibilities of using UV light to kill the Coronavirus (COVID-19). While a lot of it is plausible and possible, the usage of UV light to kill the virus on watches may be more problematic as opposed to a solution to the industry.

WORLD WILL BE CHANGED WHEN COVID-19 IS OVER

One of the first things we’ll find is that when the pandemic (at the time of this writing) is over, the watchmaking industry (and the world) will be changed. Many processes will have to be reviewed and scrutinize to the highest degrees for health and safety. This is especially true with the take-in process for after-sales service in watchmaking.

AFTER-SALES SERVICE TAKE-IN PROCESS WILL NEED TO BE EVALUATED

The repair process for service departments around the world will need to be re-examined. Considering that we do not know whether our customers and clients have been infected with the virus, how are we going to handle the watches when they come in without catching the virus?

This will be one of the biggest hurdles logistically speaking to overcome. Independent watchmakers will have a significantly easier time handling this since their operations are smaller and they can be more mobile and flexible. The bigger giants in the industry, simply due to the sheer number of employees, will have a harder time implementing, fixing, and tweaking these new protocols.

HOW DOES UV LIGHT FIT IN THIS EQUATION?

One of the biggest questions I’ve received since the COVID-19 pandemic is whether or not UV light is a good weapon against the virus. Researchers from a 2018 paper published that “continuous very low dose-rate far-UVC light in indoor public locations is a promising, safe and inexpensive tool to reduce the spread of airborne-mediated microbial diseases.”

Wavelengths of UV light in the range of 200 to 280 nm have been demonstrated to effectively deactivate bacteria and viruses due to DNA mutations induced by the absorption of UV light by DNA molecules. Since UV light exposure can kill microbial diseases before it gets into a host, it’s not unreasonable to see it is being suggested as a solution to our problem.

“CAN I USE UV LIGHT TO KILL THE VIRUS ON MY SKIN?”

NO. Do not use UV light to kill COVID-19 on your skin. Do not even attempt to use UV light to sanitize and decontaminate yourself. We are only talking about using UV light in regards to decontaminating and killing the virus on watches not on the human body and skin.

However, there’s more to the equation than meets the eye.

In this post today, we’ll go over what UV light consists of, the dangers, and the logistical questions that we will be faced with if we do proceed with UV light as a possible decontaminate against the Coronavirus.

WHAT IS UV LIGHT?

It’s important that we establish some basic guidelines first. Simply put, ultraviolet light is a form of radiation that is invisible to the eye. Radiation is a form of energy therefore ultraviolet light is an invisible part of the electromagnetic spectrum. I promise I will keep this as laymen as possible.

Ultraviolet light is part of the natural energy produced by the sun.

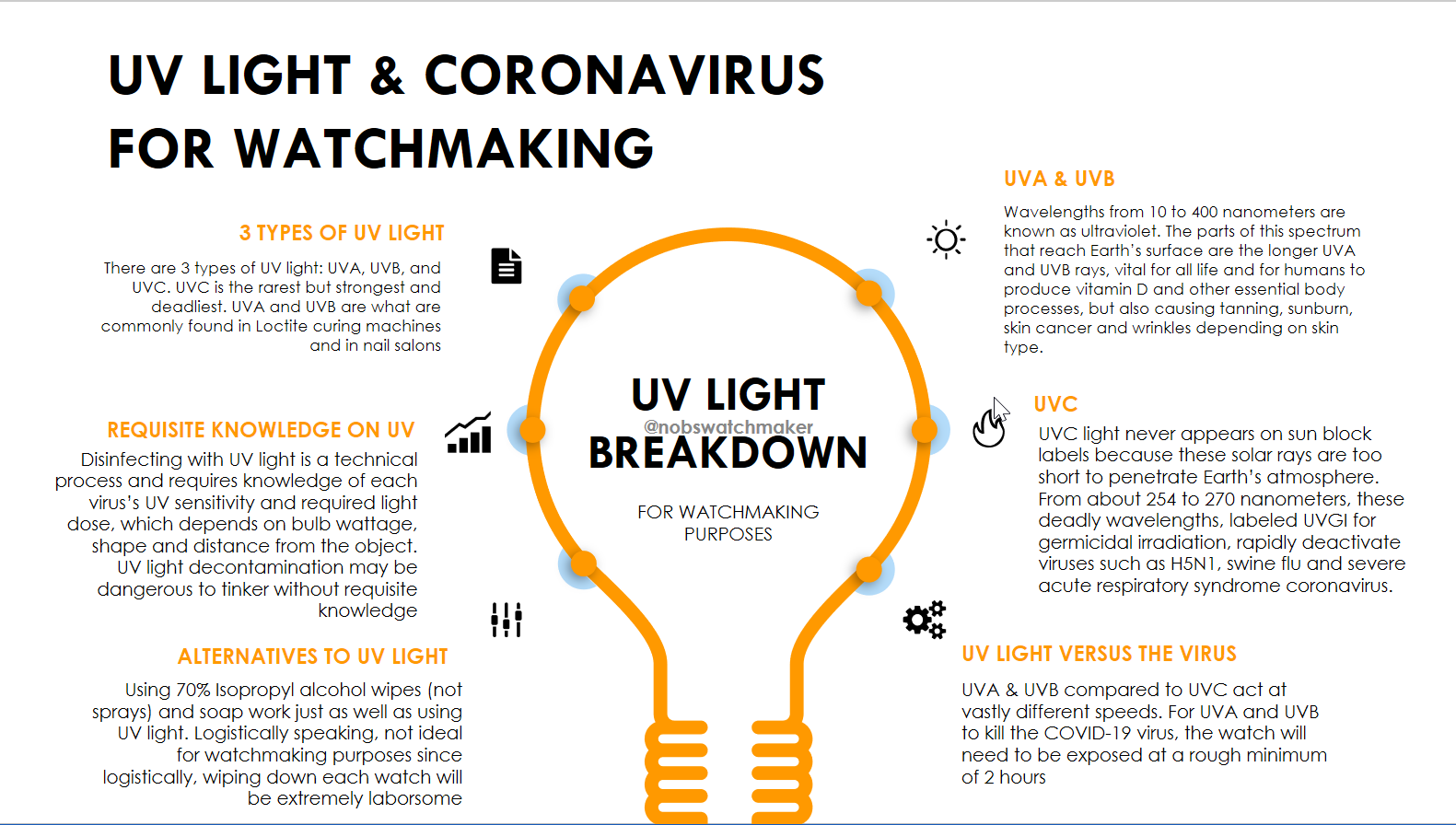

UVA, UVB, & UVC

The three common types of ultraviolet light that the Sun emits is:

Ultraviolet A (UVA), Ultraviolet B (UVB), and Ultraviolet C (UVC)

Here is a quick breakdown:

ULTRAVIOLET A

UVA = 400nm - 315nm, lowest energy

UVA is also what we commonly refer to as ‘black light’

UVA rays penetrates the ozone layers. About 95% of the ultraviolet radiation that reaches the Earth's surface is UVA.

UVA rays cause tanning, and the shorter wavelengths of UVA also cause sunburn. There is no such thing as a safe or healthy tan. UVA radiation is proven to contribute to the development of skin cancer.

UVA rays penetrate your skins deeper than UVB rays, even though UVA rays are less intense. Exposure to UVA rays can cause genetic damage to inner cells on the top surfaces of skin including the dermis. This is also how you get a tan by the way.

UVA radiation is one of the components used in watchmaking for UV glue and UV curing of crystals. Fun fact, it is also the main type of light used in most tanning beds.

UVA makes up about 95% percent of UV radiation on earth from the sun.

UVA can penetrate windows and cloud cover which is why some people can still get a tan on a cloudy day.

UVA destroy vitamin A in skin

UVA is regarded as the least harmful but can contribute to the aging of skin, DNA damage and possibly skin cancer

ULTRAVIOLET B

UVB = 315nm - 280nm, medium energy

UVB is similar to UVA in that it can also penetrate and damage the outer layers of your skin.

UVB is absorbed by the ozone layer. Prolonged exposure causes sun burn and could result in unhealthy effects on the skin and eyes.

UVB intensity fluctuates. UVB rays can damage skin year-round (does not matter whether it is summer time or not folks).

UVB rays can be filtered and do not penetrate glass.

UVB exposure is that it induces the production of vitamin D in the skin.

UVB destroy vitamin A in skin

UVB rays can burn the skin and damage eyes

ULTRAVIOLET C

UVC = 200nm to 280nm, highest energy

UVC can cause damage to all forms of life and is effective in microbial control.

UVC causes damage to the nucleic acid of microorganisms in the DNA so that when it tries to replicate, it dies. Pretty neat eh?

UVC rays are the highest energy, most dangerous type of ultraviolet light

UVC energy at 253.7 nanometers provides the most germicidal effect

UVC energy as an application to inactivate microorganisms is also known as Germicidal Irradiation or UVGI.

UVC research in 1878, found that artificially produced UVC can be a method of sterilization

DANGERS OF ULTRAVIOLET LIGHT

Many experts in the field advise against using concentrated UV light to prevent or treat the Coronavirus. With the current literature and knowledge, regular dosages of UV lights like UVA and UVB are not ideal or strong enough to kill the virus. Research on coronavirus strands like SARS (similar but different to COVID-19) found that UVA exposure for 15 minutes had little to no impact on the virus (to be fair, the study did not look at different exposure rates or even the use of UVB). This means that standing in the sun for hours may not help in killing the Coronavirus.

Therefore, the option that we are talking about is UVC.

As a disclaimer, we are not to be using UV light in to sanitize and decontaminate ourselves. This is just asking for a whole host of other problems. Only significantly high levels of UVC light can kill viruses and even at those levels will cause damage and irritation to the individual.

Now that we’ve established we are not using the UV light to kill the virus on us but rather talking about the potential applications of using UV light to kill the virus on watches, we may continue.

Dr. Pokrath Hansasuta, assistant professor of virology at Chulalongkorn University states "UV is able to kill COVID-19 if it is exposed to concentrated UV ray in a certain amount of time and distance.”

So the question isn’t whether or not the UV light can kill the virus but rather how much and how long?

UVC REQUISITE KNOWLEDGE

We’ve established that UV light can kill the virus. Now we need to figure out how much and how long it takes to kill the virus. The problem with this is that it requires a heavy degree of research and we do not have that knowledge at the moment. We do not know the virus well enough to determine how much exposure is required and for how long. The exposure rate can be different if the virus is living on stainless steel versus cardboard. What about leather straps and other various metals that bracelets are made out of? To compound the issue even further, new research tomorrow can scrap everything that was created in this post.

Here’s the short list breakdown:

There hasn’t been any research looking at how UVC specifically affects COVID-19

Studies have shown that it can be used against other coronaviruses such as SARS

Recent study suggests that UVC could be used to disinfect personal protective equipment

The problem with the research study is that it needed the highest degree of UV exposure out of the hundreds of viruses they’ve tested

Another problem with the research was that the amount of UV depended on various factors such as shape, type, material, and surface the virus was on

UVC is extremely dangerous and should be limited in terms of exposure

UVC usage requires special equipment and training therefore not everyone will be able to access this type of radiation

There is a emerging type of UVC called Far-UVC that is considered less dangerous and just as lethal to viruses and microorganisms but further research is necessary.

Far-UVC has a shorter wavelength than our normal UVC

The limited research experiments suggests that it does not damage human skin cells. Again, further research is required to see if the effects are replicable, safe, and properly evaluated

LOGISTICAL QUESTIONS FOR WATCHMAKING PURPOSES

Let’s say you have a UV light at work or at home that you used to glue crystals. Can you use that to kill the virus? Here are some concerns:

WATCHMAKING UV LIGHTS

Most of the UV light machines that we use in the industry consist of UVA and UVB rays. In theory, if you just leave the watch under the light for hours on end, it should kill the virus sooner or later. The problem is that we do not know how long and whether the concentration of the UV light is strong enough. If you own a Loctite UV curing machine, they can be helpful to a degree. The problem still remains, how long and how much?

Even then, how many watches can you place under the lamp or in the machine at once? The lamps and machines are costly to be ordering in bulk.

EXPOSURE- WHO WILL BE DOING THE JOB?

Another logistical problem you’ll run into is who is in charge of doing the decontamination? If UV light is to be considered as form of decontamination, you’re going to need someone to oversee and do it. Are they okay with the constant UV exposure? Will they be properly equipped to handle it? Who really wants to be handling watches in front of UV light the entire time?

CERTAIN MODELS, DIAL,& HANDS CAN’T BE EXPOSED

There are some models with specific dials and hands that cannot be exposed to UV light. Will the person in charge know this? The problem will be the exposure of the watch to the UV light under a specified amount of time. If you leave a watch in there for a minimum of two hours, it could wreck havoc on certain models.

STRAPS & BRACELETS

We will need to remove straps and bracelets as well. If the virus is living on the watch, it is safe to say its on the strap or bracelet. Will we be placing the watch entirely under the light and into the machine itself? Or would we have to remove them?

What about quick service- link changes, removals, strap and bracelet changes? How do we decontaminate a watch in order to remove a link safely with the usage of UV light? It will no longer be considered quick service if the client is going to wait hours for the decontamination process to be over.

CONCLUSION

The use of UV light to kill the Coronavirus is appealing and interesting. However, further research is required.

It is safe to say on an individual and independent basis, this can be done but requires a great deal of knowledge and safety in execution. For larger brands and companies, I would say the use of UV light is not feasible due to the sheer volume of incoming repairs and personnel they have to oversee. Because the organization is big, the amount of time it takes to implement new procedures will be slower. With any new procedures comes trial and errors. Fixing these mistakes will be slow as well since we will need a good deal of data first prior to executing another initiative to fix existing issues. Compared to smaller independent organizations and watchmakers, they can implement these changes almost immediately.

The use of UV light is dangerous but can be harnessed if the requisite knowledge is attained.

The logistics of UV light is where the problems will occur for both small and large companies alike. Detailing a specific outline to handle these questions are crucial in developing a well thought out decontamination strategy using UV light as the primary source.