The Art of Oiling in Watchmaking - Lubrication 101

DISCLAIMER: Specific oils and lubricants will come and go. The ones that I’ll be going over here are the current “accepted” standards of watch repair. The following practices may become obsolete. New lubricants and standards are still being developed to push the boundaries of average service cycles.

THIS IS NOT INTENDED TO REPLACE HANDS-ON EXPERIENCE WITH PROFESSIONALS.

MORE PEOPLE TINKERING WITH WATCHES NOW

It seems that a lot of people have started to tinker with practice movements (which is pure awesomeness). Please see How to Get Started in Watchmaking here. I’ve gotten a good amount of questions from people who are just getting into watchmaking about oiling though. The overwhelming majority of questions are coming from watchmaking students in school and aspiring watchmakers at home that want to get even more serious.

FUNDAMENTALS:

WHY IS LUBRICATION IMPORTANT?

Lubricating a watch reduces friction against rubbing parts. As we all know, everything in a watch is connected in some shape or form. Generally, less friction is better.

WHEN IS LUBRICATION APPLIED?

We start the process of oiling usually after the movement comes out of the cleaning machine. I tell students all the time, once that movement comes out of the cleaner, that watch is the cleanest it’ll ever be. Anything you do to the watch should add and not subtract from the quality of the movement.

DO NOT LUBRICATE THE WATCH IF IT IS NOT CLEANED PROPERLY

It’s important we start lubricating AFTER the watch comes out of the cleaner. If the movement, parts, bridges, jewels, etc. are dirty or not clean during the oiling process, you are doing shoddy work. It is bad workmanship to oil without proper cleaning first. Dust, dirt, and debris from the movement may still be present which will create a grinding paste. Lubricating incorrectly will cause the oil to spread and deteroriate earlier rather than later.

Any application of oil on an already dirty movement will only have a temporary effect and will in the long term only make matters worse.

Here are some examples of poor oiling issues with some context from my Instagram account:

DO NOT CHEAP OUT ON OILS AND LUBRICANTS

One of the most common mistakes I see independent watchmakers do is cheaping out on quality oils. They buy cheaper generic versions of the oil or start experimenting with other oils from different industries. I’m not saying it’s bad to experiment. After all, a lot of things in the watchmaking industry today are from other industries (another secret the industry doesn’t tell you). All I’m saying is buy the right oils for the job. If the technical guide is telling you to use Jismaa then use Jismaa. Don’t use motor oil from your '92 Honda Civic.

The cost of quality oils is cheap compared to the cost of a watch coming back. It’s the back bone of a successful service- treat it as such.

CHECK THE EXPIRATION DATE WHEN BUYING

Expiration date is due 2021! It would definitely suck for this to get contiminated before then.

A lot of people do not know that lubricants expire. I’m being dead serious. I’ve met several watchmakers who did not believe in replacing their oils until the bottles run out (their bottles could be older than you and me combined).

Expired lubricants lose it’s effectiveness and may shorten a service cycle. A good rule of thumb is to minimize any amount of chances that may cause a functional issue. Replacing expired oils is CHEAP in the grand scheme of things.

I get complaints from independent watchmakers telling me that it’s costly to replace expired oils and that it’s not necessary. If you only have $10 dollars in your bank account then you’re right. Expired oils is probably the last thing you should be worried about.

PRO TIP: Factor some of these costs into your repairs and you shouldn’t have to worry about it. If you know your oil is expiring in 2019. Divide the cost by the amount of months left until it expires and then tack it onto the estimate bill. If you’re proactive it could literally be as small as a $5 increase on an estimate for a customer.

"THE ART OF OILING REQUIRES NOTHING SHORT OF PERFECTION"

Remember this quote. If there’s anything you take from this entire post, it’s that oiling is serious work. Your hands must be surgeon-level steady. We’re often oiling parts that require 50X magnification such as the co-axial escapement. A small amount of extra oil could mean the difference between a 2 year service cycle versus a 8 year service cycle.

This is a 50X magnification on a co-axial escapement

3 COMMON TYPES OF OILERS

Simple Oilers

This is a simple oiler. Notice the grove and shape of the nib itself. Simple and straight to the point (no pun intended).

These are your common oilers that you can find in any watch supply house. Although simple, it gets the job done. This is really all you need to get started if you’re beginning to oil.

If you've never oiled before- get these. It’s inexpensive, easy to see the amount of oil on the tip, and cost effective to replace if the tip gets broken.

Watchmakers will have their own preferences of what type of oilers to use but you really just need a simple oiler to get the job done. In skilled hands, simple oilers can get the job done for anything.

Precision Tip Oilers

This is a Precision Tip oiler. Pay particular attention to the tip of the nib. Notice how it's curved and shaped to grab a specific and exact amount.

If you have the money, these are awesome. I personally like these a lot. It's not necessary but it definitely gives you a consistent and correct amount of oil each time. These come in a variety of sizes for different jobs.

Again- YOU DO NOT NEED THIS. You don’t need to buy a Ferrari to drive to work when a Toyota does the same job.

This is an Automatic oiler. Very common in the industry amongst brands. Great for repetitive work where you know the specific amount of oil you need over and over again.

Automatic Oilers

Automatic oilers are great if you're working on the same movement repeatedly. We're able to dispense a specific amount of oil each time we use it. You'll commonly see these in manufacturers where the watchmakers are working on the same set of calibers over and over again.

If you're working at the retail level or in a shop where all types of movements come through your hands, I would highly recommend you set the quantity to the movement that comes through most frequently. I know some watchmakers who buy multiple versions of these for different types of jewels, etc.

You really only need just one. At the end of the day- automatic oilers are used to save time and speed up work efficiency. You should still know how to do oiling by hand.

FUN FACT ABOUT THE HISTORY OF WATCH LUBRICANTS

Watchmaking lubricants used to be purely animal and vegetable oil. This is also the reason why older watches may smell like fish when you open it up. Watchmakers used to use sperm oil from sperm whales as a lubricant. It worked really well (considering the technology at the time) except the fact that it would gum up within several months.

It's a good thing and a bad thing. It's bad in the sense that the watch would literally stop running within several months because the oil would gum up into an extremely thick substance. It's a good thing because the watch would be well preserved with little to no wear on the pivots.

Today's synthetic oils are the complete opposite. Since it's synthetic, it doesn't gum up at all. Watches can run well past the life span of synthetic oils. When we use animal/vegetable oil, the lubricant eventually gums up due to natural occurring substances. On the other hand, synthetic oil literally dries up and evaporates. This leaves the pivots running dry on the jewels which will cause added friction and wear on the pivots. Added friction and wear on the pivots will eventually cause metal sheering and gunk to build up (one of the reasons why overhaul is recommended after several years).

7 COMMONLY USED LUBRICANTS

There are many types of lubrications and each brand will categorize them differently. So I’ll go over the common ones.

MOEBIUS 9010- Light synthetic oil. Generally used on high speed and low torque/pressure areas. Commonly used for: Balance cap jewels, escape wheel, and seconds wheel.

HP 1000 or HP 1300 - (Fun fact, HP stands for High Pressure) Heavy synthetic oils. Generally used for high pressure/torque and low speed areas. Commonly used for: Barrel arbors, center wheel, and third wheel. Some brands will also use this for the setting system and calendar mechanisms. There are differences between HP 1000 and HP 1300 (such as viscosity etc.) but we’ll go into that another time.

MOEBIUS D5- Older version before HP1000 was introduced. Watchmakers used to MOEBIUS D5 before HP1000 was introduced. It's rumoured that one of the main reasons the industry dropped D5 was because there were still some natural oil components in it (instead of being 100% syntehtic).

MOEBIUS 9415- Generally only used for pallet jewels/stones. The thick substance holds it's own for high speed contact. Watchmakers use this specific oil for the escapement while other brands such as Rolex may use RL2

MOLYKOTE DX- Greasy paste normally used for setting systems and other high friction areas. Lots of brands for a LONG period of time have used Molykote for their setting systems because of reliability. Molykote wasn't even originally designed for watchmaking use!

Brands such as Breitling and Rolex have since rejected and discontinued using Molykote. As of the late, the reasoning is because it contaminates the cleaning solutions.

KLUBER P125- Commonly used for the mainspring barrel in automatic and manual wind watches. It's used as a breaking grease. It's very thick. It's high viscosity makes it a great choice in the barrel. We'll usually lace this lightly around the sides of the barrel walls. Make sure that you're careful when using this. Do not get it on the top/bottom lids of the barrel.

MOEBIUS 8200- We'll use 8200 for mainsprings (some use it on the setting system for older watches). Generally, we'll clean mainsprings with Solvent H. After which, we'll run a small amount of 8200 onto the entire length of the mainspring itself. 8200 has been a staple in many technical guides. Other brands may have different standard operating procedures so again, this is just a generalization.

FIXODROP EPILAME- Although not an oil or lubricant, I couldn't talk about oils without mentioning Epilame.

The most basic explanation of Epilame is that it's used to change the surface tension on a part so that oil doesn't run off or spread. Some common parts we'll use Epilame on are the escape wheel, pallet fork jewels/stones, tip of the seconds wheel, cap jewels, and reverser wheels.

Take a look at this image here. This is your average and common jewel on a gear train that we will oil. This should serve as a GUIDELINE and reference only.

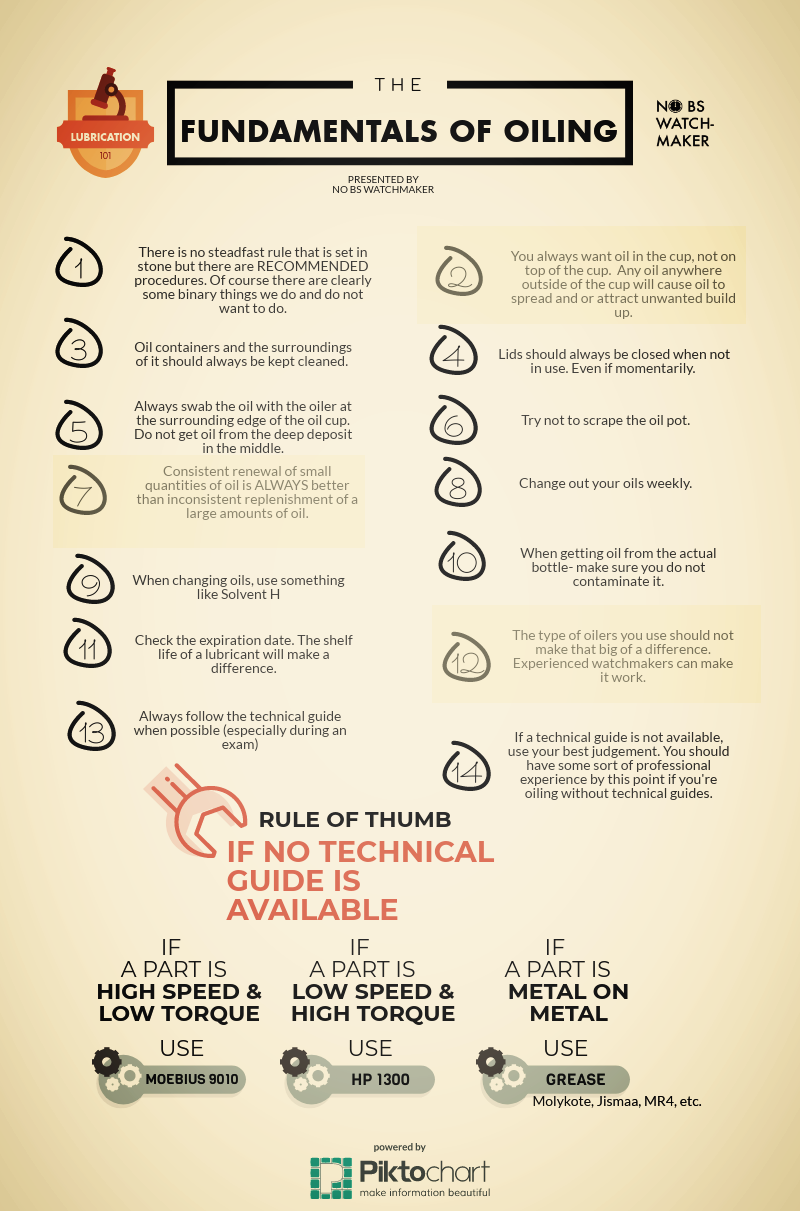

FUNDAMENTAL OILING PRINCIPLES TO REMEMBER

There is no steadfast rule that is set in stone but there are RECOMMENDED procedures. Of course there are clearly some binary things we do and do not want to do.

You always want oil in the cup, not on top of the cup. It should not be anywhere else other then inside the cup where the pivot is. Any oil anywhere outside of the cup will cause oil to spread and or attract unwanted build up.

Oil containers and the surroundings of it should always be kept cleaned. Any build up around your oil container will make its way into the oil irregardless of the lid being closed

Lids should always be closed when not in use. Even if momentarily. You should be opening it to grab the oil with your oiler and closing it immediately. Again, it’s worth repeating. The oil lid should only be open to grab the oil and closed right afterwards. Do not grab the oil, proceed to oil the part, and then close the oil lid when you’re done. This is how oils get contaminated quickly.

Always swab the oil with the oiler at the surrounding edge of the oil cup. Do not get oil from the deep deposit in the middle. This is because dirt, dust, and other contiminants will usually make it’s way to the deep deposit in the middle of the oil cup.

Try not to scrape the oil pot. Depending on the material of your oil cup, it could transfer small fragments of debris to your watch.

Consistent renewal of small quantities of oil is ALWAYS better than inconsistent replenishment of a large amounts of oil.

Change out your oils weekly. Yes. Weekly. Do not skip this step.

When changing oils, use something like Solvent H to clean the oil pot. Do not just simply wipe it with paper.

When getting oil from the actual bottle- make sure you do not contaminate it. You have no idea how many watchmakers I’ve seen with contaminated bottles that still had 9/10 of the bottle to go.

Check the expiration date. The shelf life of a lubricant will make a difference. You might not think it will but in the long run, it does.

The type of oilers you use should not make that big of a difference. In expert hands, any average oiler should do the job.

Always follow the technical guide when possible (especially during an exam)

If a technical guide is not available, use your best judgement. You should have some sort of professional experience by this point if you're oiling without technical guides.

Go slow and steady when oiling. Slow is smooth and smooth is fast.

Do the oiling job right the first time around. It's easier to take your time and do it right the first time around then to go fast and mess it up. Cleaning up is time consuming and high risk.

Don't depend on Rodico too much. The use of Rodico should a last case scenario. Rodico is great! Except the fact that most watchmakers keep them for years on end and never change/throw them out. If you do use Rodico, make sure it's less than a week old since opening.

Generally speaking:

If a wheel is high speed low torque- USE MOEBIUS 9010

If a wheel is low speed high torque- USE HP 1300

If it's metal on metal (think setting system)- USE SOME FORM OF GREASE (MOLYKOTE, JISMAA, MR4, ETC.) Some technical guides will also tell you to use HP 1300.

HERE'S QUICK RECAP OF THE FUNDAMENTALS IN A DOWNLOADABLE INFOGRAPHIC

Right click and download!

LIKE WHAT YOU READ? YOU'LL LOVE THE BOOK

I go over 31 essential watchmaking tools you'll need, 11 essential pieces of advice for aspiring watchmakers, and how I would theoretically get someone ready for a watchmaking bench test in 8 weeks.